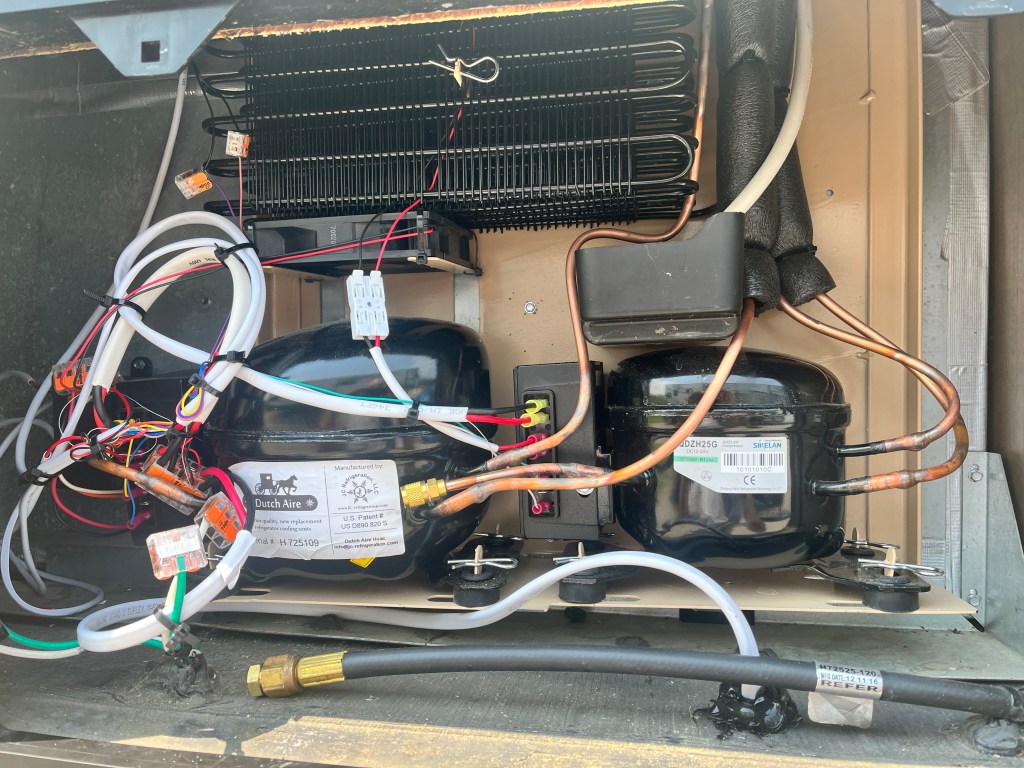

A light rain tapped the aluminum canopy roof over my head as I emptied the last bag of ice I hoped to buy into my cooler where we were keeping our perishables. We had just parked our motorhome in the parking lot of Adventure RV in Shipshewana Indiana. We were there for a major repair to our RV refrigerator. One of the reasons we chose our model of motorhome was because it came with a 2 way propane/electric refrigerator. This allows use while unplugged from A/C power. Unfortunately, unlike the smaller refrigerator in our old motorhome which was capable of turning a live kangaroo into block of ice, this big 18 cubic foot cold box was almost anything but cold. It hadn’t really worked well since day one. We always wound up with sour milk and brown lettuce. So here we were getting the guts of the unit removed and replaced with a dual-compressor 12 volt system built in Shipshewana by JC Refrigeration.

Adventure RV is the newly founded service and installation arm of JC Refrigeration who are the builders of Dutchaire RV refrigerators. JC Refrigeration has been building good RV refrigerators for 45 years. In addition to brand new units, they have also been building and installing conversion systems for problem units including our Norcold (NeverCold?) Polarmax 2118. I had heard nothing but good things so called to schedule an appointment to solve our refrigerator issues once and for all.

I had several conversations with Aaron who manages Adventure RV. We arranged to stay on-site the night before our scheduled work. Our appointment was bright and early on a Thursday morning. We had already booked a trip to Michigan beginning the following week. It was a relatively easy task to add a couple days and include a stop in Shipshewana.

Thursday morning, we backed in to the service bay and I spent a few minutes reviewing the repair with Aaron. The details of the actual work would be a bit boring but the ongoing need for such work was apparent. There was a veritable refrigerator graveyard in the rear of the shop. Aaron said they had way more than that piled elsewhere for disposal. He said “Business is brisk thanks to Norcold and Dometic.” (Dometic is another major player in the RV appliance business.)

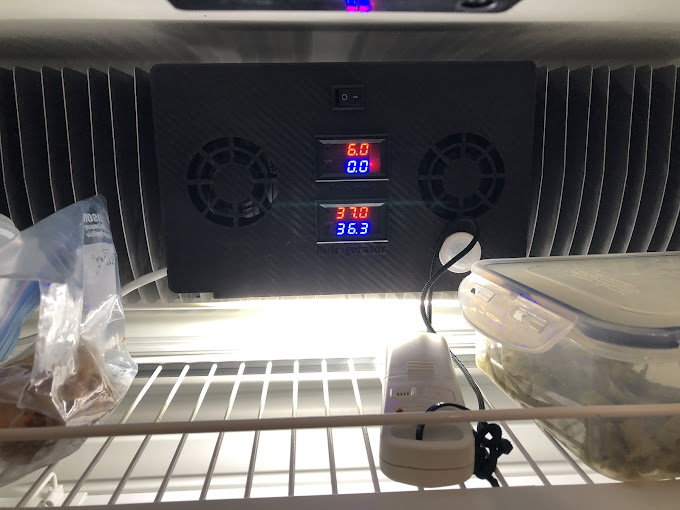

We went on to enjoy the morning sightseeing and shopping around Shipshewanna. Aaron and his crew pulled out our refrigerator, gutted it, and made it whole again. We returned to Adventure RV around 11:30 to find the refrigerator temperature was already down to 38 degrees. This after being plugged in for all of an hour. It used to take 20 hours for the old system to get that cold. Suffice it to say, our refrigeration problems in the motorhome seem to be solved.

What’s that you say? Why the boring tale about getting an RV refrigerator fixed? Please be patient and bear with me. We’ll come back to it.

Once the RV (Revenue Vacuum?) repair was complete, we resumed our expected travel plans. We headed a couple hours north to Dearborn, Michigan to visit “The Henry Ford“, Greenfield Village, and “The Rouge“. The latter is a state-of-the-art manufacturing plant where the Ford F-150 is built.

We arrived at The Henry Ford before they opened on a Saturday and bought our all access passes. These got us into the museum, the Rouge, Greenfield Village, and the Big Screen theater. The pass also included the bus, Model T rides, and the train at Greenfield Village. More on that later. Our first order of business was to hop on the transport to go see The Rouge.

We have been on tours of manufacturing facilities before. The first was back in 2008 when we visited the Winnebago plant during the Winnebago Grand National Rally. It seemed impressive with something like 7 production lines all moving at once. We watched bare chassis slowly move down an assembly line as workers buzzed around like bees. They added walls, appliances, flooring, and accessories. As each would-be unit moved down the belt it became more and more RV-like. The final product was driven off the line at the end of the building. We were guided to different stations where we saw each piece being made. We nodded and said “very interesting” a lot. It was impressive. We also saw the Georgetown factory in person though not while the product was being built. Still, the tour and facility were fun to see.

But the Rouge at Ford is different. There is truly a Wow factor here. The “wow” starts with the enormous green roof that supports its own ecosystem. It continues with an A/V presentation on the history of the Ford Motor Company. After the history lesson, we moved to another threater. Here we saw an amazing presentation that showed the process of building a new F-150. These two presentations would have made the tour worthwhile. Then you get to go out on the assembly area and see if for real. (Caveat: they don’t work Saturday so we’ll have to go back some day and see it things in action.)

I’ll admit the videos really got the wheels spinning in my head. In history class, we always hear how Henry Ford didn’t invent the car but the assembly line. That is such a ridiculous understatement to the impact Henry Ford had on America.

I’ll admit to never knowing much about Henry Ford story. (I was always kind of a Chevy guy. LOL!) It is probably safe to say without Henry Ford America would likely not be where it is today. Henry grew up on a farm but, even as a child, preferred grease under his nails rather than manure. Early in life he became enamored with a huge piece of self-propelled equipment he and his father encountered on the road during some bit of farming or another. From that day forward, young Henry was obsessed with engines, machines, and all things mechanical.

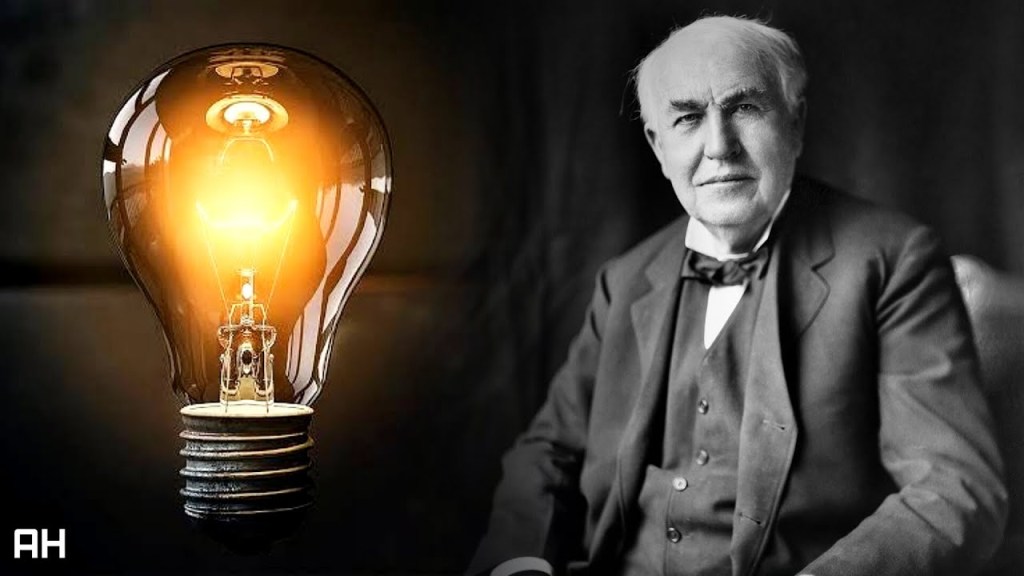

In his adult life, Henry became good friends with Thomas Edison. He worked as chief engineer at the Edison Illuminating plant in Detroit. But Ford’s real passion was the internal combustion engine. Specifically, he dreamed of one day building a car that everyone could afford. Late at night, he would work in a small shed in the back yard of the duplex he lived in. Finally, with the help of his wife, he was able to successfully start his first engine at the kitchen sink.

There are about 10,000 more steps between this first tiny success to the first Model T being built in 1908. The first one cane off an assembly line in 1913. In between there were two failed attempts at starting a car company and many other advances and setbacks. I’d suggest the reader visit “The Henry Ford” to really get an appreciation for the determination of the young farmer-turned-mechanic. Suffice it to say, the man was a visionary. With encouragement from Edison, Ford went on to truly fulfill his dream of building an affordable car for the masses.

One infamous moment in the history of the Ford motor company was “The Battle of the Overpass”. Henchman hired by Ford to keep the union out, physically attacked the representatives of the UAW. This attack, along with pressure from the government and his son Edsel, turned the tide of public opinion against Ford. Ultimately he relented and allowed the workers to unify. One can only imagine the brouhaha that would have ensued with today’s social media. It is worth mentioning this because, Ford felt he had done more for his employees than any member of industry. In fact in 1914 Henry had doubled worker’s wages to $5.00/day. In doing so, he hoped to incentivize workers who dealt with the monotony of the assembly line. He wanted to retain experienced, tenured employees. (Modern corporations could learn a lesson here.) Ford also thought more about ergonomics than most employers of the age or really, any age. Assembly lines were built to make it easier for workers to do their jobs without suffering injuries from repetitive movement. Ford understood that sick, injured, or absent employees slowed production.

When wages were doubled, the Rouge exploded in people and capacity. Workers came to Dearborn from all over the world seeking work. The population of the Rouge grew to 100,000 people! Read that again: Dearborn, Michigan in the heartland of the USA was the world center for industry. People wanted to come to the USA to work. They did every job imaginable in and around a manufacturing plant. Everything from pushing wheel barrows and shoveling coal to test driving new Model Ts around the yard and everything in between. One can only imagine the bustling businesses in and around Dearborn needed to support 100,000 workers. There were people working in restaurants and hotels, cooking, cleaning, serving food, washing laundry. Farmers must have hired plenty of hands to grow and harvest the food needed to feed throngs of workers.

These days, the Rouge is home to a modest 1,400 workers. Many of the 100,000 jobs have been replaced by modern processes and machinery. Many parts and raw materials are created elsewhere around the world. Robots stamp out, move, and paint the truck bodies before being turned over to teams of humans for assembly.

After the videos, we walked the catwalk overlooking the assembly lines with a tour guide. I marveled at the automated lines moving parts and bodies to and fro toward final assembly. In full production, one new F-150 is produced every 53 seconds. 1300 trucks a day. 300,000 trucks a year. They are all sold before they are built. In my mind I tried to imagine what the floor looked like 100 years ago. Every inch of the floor must have been covered with people, equipment, and parts. I can’t even imagine the noise.

We completed the loop of the Rouge assembly floor. We checked out some of the awesome examples of cars produced there over the last 100 years in the lobby. We then boarded the bus back to the museum to explore there.

I’m not normally a big museum enthusiast. Depending on the museum, one finds the content is a bit of a stretch. The museum topic will have one main attraction but the wow factor quickly diminishes with the level of minutia. Not so with The Henry Ford. Locals actually get annual memberships there and visit all the time. To really take it all in and absorb all there is to learn, one could spend a few days.

The Henry Ford is not a car museum. It is a museum dedicated to American Innovation featuring everything from the steam era forward. Yes, there are cars there. This includes a really cool walkway starting with Model T era cars and continuing into the early 2000s. There is also an entire section dedicated to auto racing including a room featuring “Ford versus Ferrari”. There is also furniture, agricultural equipment, planes, and trains. There is general Americana including a walk through time showing household goods from the early 1900s to today. It was in this section where I felt my age. I overheard a father explaining to his teen-aged son how a dial telephone worked. Ugh.

One interesting note is that The Henry Ford has a rather large section dedicated to freedom and civil rights. Interesting because Ford was a vocal anti-Semite. One can only guess how he developed such ideas but the tribute to civil rights is moving.

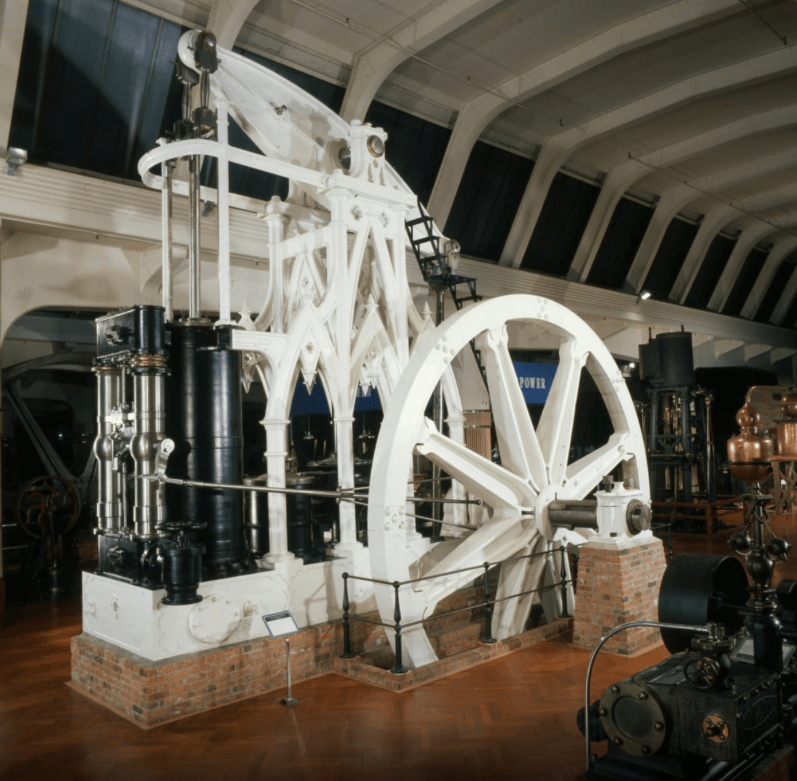

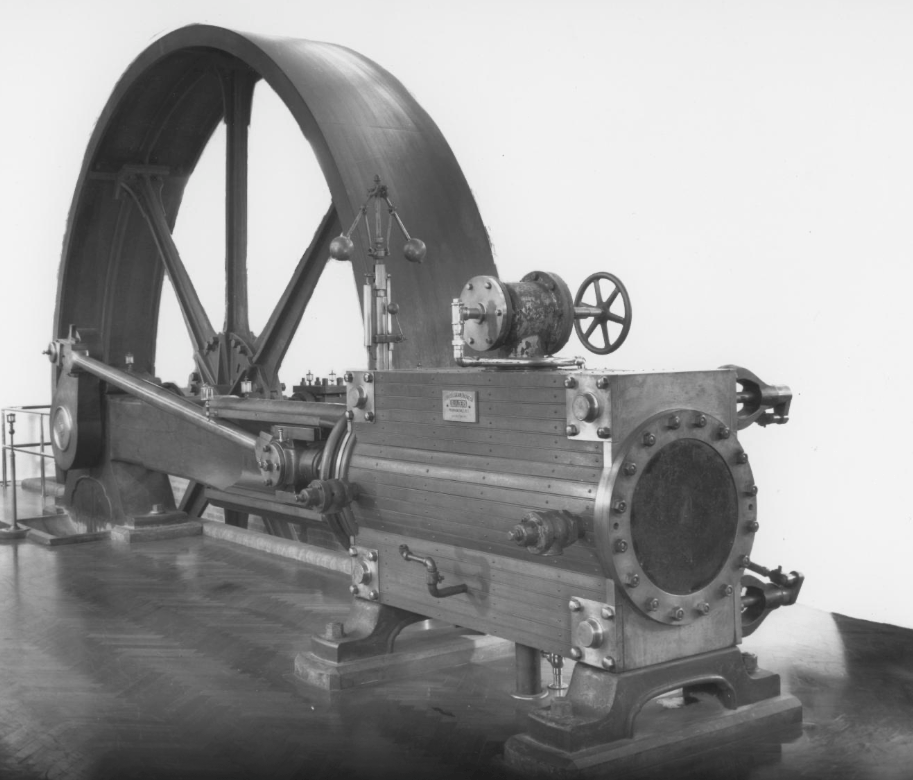

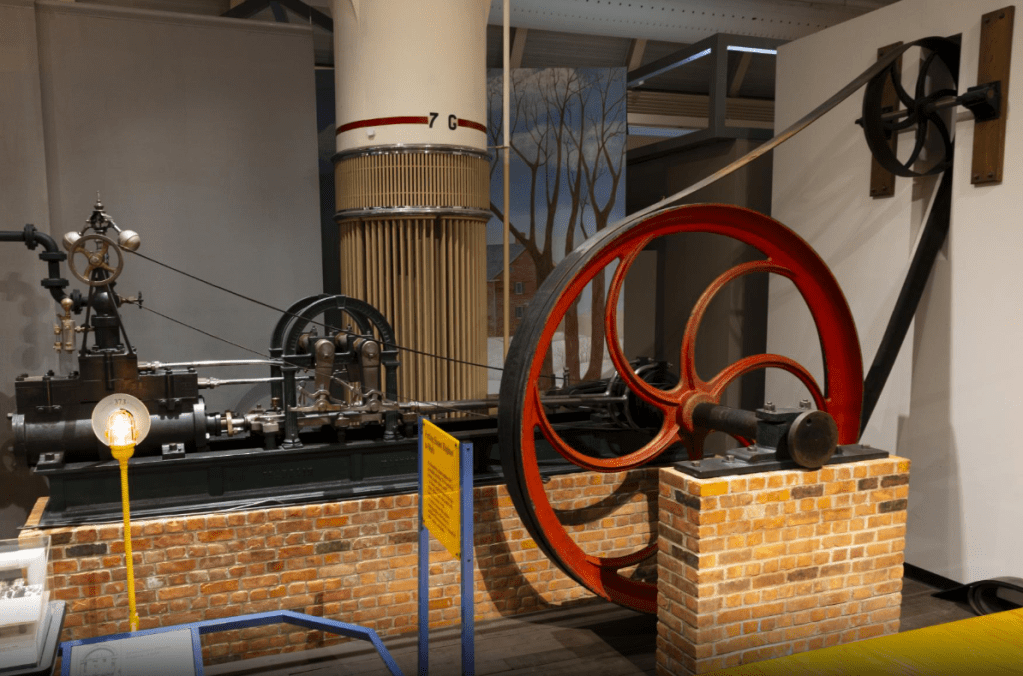

Perhaps the most impressive display is the large number of original steam engines that powered industry across America. These are not reproductions. They are the actual engines moved to Dearborn and built into suitable (sometimes original) structures for display. Steam was the driver of early American industry. The engines are mechanical works of art: strong, elegant, beautiful, dangerous, and huge. They required high maintenance but put out huge amounts of power. The engineers who cared for and ran these machines must have been proud of the work they did.

There was room after room displaying the machinery driven by the belts that were turned by steam. Every piece of equipment at the museum looks as though it could still be used today. In a pinch, one could fire up one of those steam engines, rig a few belts to a spindle and create whatever their imagination allowed. While the displayed machinery was not computer driven CAD/CAM type stuff nor was it 3D printing, it would surely outlast today’s circuit board and computer driven tools.

This is proven out at Greenfield Village where an actual machine shop is setup. Some of the tools are regularly run for demonstrations. Sadly, the belts that run the machines are turned by electricity instead of steam. The usage of the tools is the same. We watched as a craftsman ran a lathe and press to produce a brass candle holder.

Elsewhere in Greenfield Village one finds such trinkets as the shed where Henry Ford built is first motorized Quadracycle. There is much more here about the early life of Henry Ford. There is also a huge section dedicated to his main mentor: Thomas Edison. Again, we all learned in high school history about the invention of the light bulb. One quickly gets the idea that Edison only invented the light bulb to be able to see better for all the other stuff he created or improved. The idea of capturing the vibrations of the human voice on media seems as fundamental to us as the round wheel but both were revolutionary, life-changing discoveries. To walk the Edison offices, homes, and workshops and see the intricate equipment built long before computer aided design and cheap foreign labor is inspiring.

Wandering The Rouge plant, The Henry Ford, and Greenfield Village took my mind back 100 years. It was a time when American visionaries foresaw ways to make life better. More importantly, they recruited Americans to bring these ideas to fruition. They didn’t come up with a prototype then go find the cheapest place on earth to get the work done. They built stuff well and built it to last. Not to be replaced every couple years. Nowhere is this more obvious than the fact that there are still a couple hundred thousand Ford Model Ts on the road today. The last one rolled off the assembly line 100 years ago. Anyone think there will be a Prius on the road in 100 years?

In 1925 America truly was the land of opportunity. Companies like Ford and hundreds of others provided good jobs to those willing to come here and work. I doubt anyone cared about how someone immigrated. Just whether or not they were willing to put in a solid 8 hour work day. For his part, the workman could expect to take home a living wage for a good day of work. He could go to bed knowing he helped do something substantial and contributory to the American way of life.

Was it all peaches and cream? Of course not. There were, no doubt, predatory business owners and those not as insightful as Henry Ford when it came to understanding the needs of his workforce. But organized labor (despite its many faults) balanced the scales as life moved forward.

I spent a lot of time behind the wheel of our motorhome as we traveled about other parts of Michigan. It was a lot of time to think. Where are we now as a country? After the Great Depression and World War II life seemed to continue to boom into the 1950s. But then things changed. US companies seemed to lose some of the visionary leadership and refused to adopt to newer technologies. Not so for Asian companies. Asia began siphoning off things like steel production and were better prepared for the electronic age. I remember watching the news in the 1970s as more and more factories shutdown and were abandoned as jobs moved to other countries. Clothing and other textiles soon followed.

Enter the information age. Computer tech became the next big thing. Innovation switched from internal combustion engines to computer terminals. I learned to program on some of the earliest home computers. The TRS 80 from Radio Shack, the Commodore 64, and others. We brought the computers home, turned them on, and installed the operating system. A blinking cursor from a green screen stared expectantly back at us. Now what?

The “what” was convincing the world they needed computers. Fortunately, there were a few visionaries out there that saw what could be done with a computer if done right. The problem was convincing the potential customer of the need and also not solving problems that didn’t exist. The latter, in my opinion, has been a major flaw of many endeavors at building software companies.

More importantly, the information age was the beginning of the removal of workers from a tangible product. Sure you could find a terminal and run your company’s code and see it on the screen. But was it the same as driving a completed Model T off the line for a waiting customer? Making a computer do something productive required more training than installing a radiator on a car on an assembly line.

Still, the early years of the information age were not much different than the early years of the industrial age. Lots and lots of people were needed to write the voluminous lines of code it took to make the information world go round. Corporate centers boomed and spawned dozens of small businesses in all the big information centers. It took armies of contractors, restaurants, and maintenance workers to keep those busy IT centers buzzing to the hum of circuit boards and CPUs.

Just as we saw manufacturing begin to dwindle, so too have we seen American involvement in the information age dwindle. American manufacturing jobs lost out to inexpensive workers from the remote corners of the globe when shipping became viable. Likewise, the internet suddenly gave places like Eastern Europe, Asia, and India the ability to provide inexpensive “labor” to the computer software industry. Good programmers could be hired for pennies on the dollar versus expensive American workers.

In 2020 the world stopped going to the office when COVID-19 hit. Those small businesses for whom the corporate world was the lifeblood dried up. Meanwhile, the need to work remotely drove the creation of new and better collaboration tools. The same tools reduced the need for workers in any particular physical location enabling even further exports of jobs to other regions.

Another heavy hammer has hit the American IT worker and IT workers around the word as Artificial Intelligence blossoms. Suddenly, computers could write their own code, fix themselves, and perform other tasks that a human was previously needed for. Humans created AI. AI eliminates the need for humans. It very much reminds me of the days when the Pennsylvania coal miners were tasked with setting up automated coal mining machines. Once done, they were told they were no longer needed. The machines would handle their jobs.

All this I considered while tooling around the highways of Michigan. I thought about what must have been glorious times in the roaring 20s when everyone that wanted to work had a job. It must have been wonderful to see a Model T rolling down the street and think “I helped build that.” There were not the massive public assistance programs we have now that remove the incentive to work. Employers like Ford were concerned about their employees being able to afford the products they were building. Now it seems, there is much more concern for what the shareholder can afford than the employee.

Will there be another golden age in the US? Do we have more visionaries on the rise to lead the way with nothing but a dream? Is it possible there is really something to using things like tariffs to level the playing field and give the American worker a fair chance again? Do we as a people still have the drive that those workers in the 1920s had? More importantly, will today’s profit-driven corporations ever allow true quality back in to the production cycle? If they do, will Americans be willing to pay for it? History says no.

From watching the RV industry, as much as people complain about quality, they still buy on price before anything else. I won’t disparage brands here. There are several out there that are built to and sold for a rock bottom price point. I’ve seen them literally falling apart while going down the road. Yet they outsell better built units 3 to 1.

Referring back to to our refrigerator story that started this rambling mess, our refrigerator was built by Norcold who was once a reputable manufacturer. RVs are just a box of 3rd party components rolling down the road. No RV manufacturer builds all the pieces themselves. They source things like appliances and furniture elsewhere. Prices must remain low to appeal to consumers who look at the bottom line before all else. It becomes the perfect storm of less than-stellar-products built with less-than-stellar care all making a less-than-stellar experience for the end user. Oddly, the products built by Dutchaire are US-based manufacturing and are of very high quality. As far as I know, they aren’t packaged as OEM equipment in any major RV brand. The cost conscious consumer must then spend money they didn’t spend on the RV replacing something that shouldn’t need it. It becomes the old pay me now or pay me later story. The point is we do know how to build good stuff. We choose not to because we are vying for the buyers who still look at the price before anything else. Can tariffs help with this? I’m not a student of economics and can’t answer that. I can say that after getting a look at America’s glorious past, I’m willing to give her a chance. I plan to make a focused effort to buy American where I can.

Will simply “Buy American” make things better? Maybe not. But I think consumers need to change our expectations and focus on long-lasting products with less bells and whistles. Why are we okay with household appliances that cost a fortune and need to be replaced every few years? We get excited over the fact that a slow cooker is internet enabled so it can be turned on and off with a phone app. We are delighted that our refrigerator can help make a grocery list and place an online order. But then in a couple years that fancy refrigerator blows a printed circuit board and all that expensive food winds up in the trash can. Meanwhile, I have a freezer in my garage purchased circa 1985 that still works great! That is what we should be demanding. We know how to build things that last. Let’s do it!